Polymer scientists at Stellenbosch University have developed a novel method to break down lignin – a by-product in the paper manufacturing process – into valuable chemicals that can be used as raw materials in the chemical and polymer manufacturing industry.

Lignin is one of the main components of trees and plants, but chemically it is extremely difficult to break down into simple molecules. Worldwide, the paper industry produces approximately 50 million tonnes of lignin per year as a by-product. Even though it could be exploited to provide us with an alternative to fossil fuel-based polymers, most of it (98%) is simply burned to fuel the paper mills.

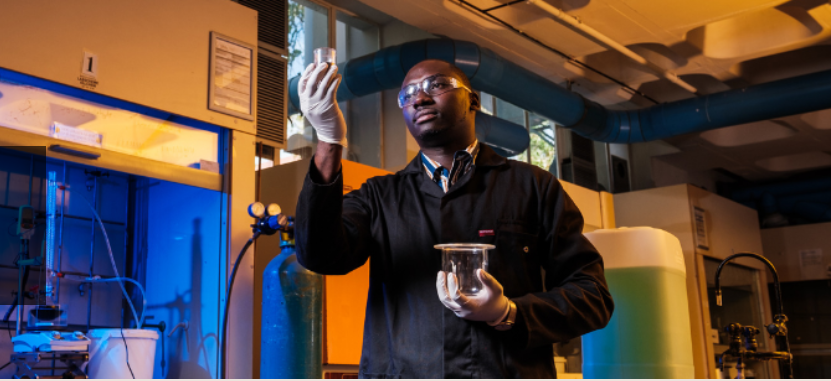

Dr Ndumiso Sibanda, who developed the method as part of his doctoral thesis, says he is specifically interested in finding innovative and tailored scientific solutions to some of the more challenging questions facing the polymer, pharmaceutical and plastic industry. He will receive his PhD during Stellenbosch University’s autumn graduation this week.

“My interest in biorefinery development was stimulated when I became part of Prof Harald Pasch’s research group in 2017 as an MSc student. Biorefinery methods are very valuable in our current society, where waste accumulation and resource depletion have negative social and environmental impacts,” he explains.

Prof Pasch’s research groupp in SU’s Department of Chemistry and Polymer Science is regarded as one of the leading groups in this field. Another expert in the group is Dr Helen Pfukwa, who has done extensive research on lignin valorization. On top of revalorising an agricultural waste product, this type of research opens the way for lessening our dependence on fossil fuels, by replacing fossil fuel-derived polymers with environmentally friendly bio-based polymers.

Dr Sibanda says lignin has a very complex but versatile molecular structure, which makes it possible to synthesise new functional polymers that can be used as drug delivery vehicles, biomaterial synthesis and smart polymer synthesis.

“Generally, polymers that have been synthesized from lignin-derived monomers and their derivatives have high glass transition temperatures (called Tg’s) and are thermally stable with good mechanical properties. This makes them appealing replacements for fossil-fuel derived styrene in the synthesis of high temperature-resistant plastics, advanced composites and resins.”

The method has since been patented, and they are now working in collaboration with SU’s Department of Process Engineering to upscale the method: “We are currently at technological readiness level 5, which means we are working on an integrated approach to provide a bridge from laboratory testing and validation of the protocol to pilot testing in the factory.”

How does the technology work?

Lignin is a very complex macromolecule with a unique structure. The structure also differs depending on the origin of the wood and how it was pre-treated.

Chemists use oxygen to break down these complex macromolecules (called polymers) into smaller molecules (called component monomers) in a process called depolymerisation. In the case of lignin, however, most mild oxidative techniques do not lead to the complete conversion of lignin. Furthermore, if the process is not controlled effectively, over-oxidation may lead to structures that are even more complex than the starting lignin itself, Dr Sibanda explains.

His method, which rests on the work done by Dr Pfukwa, addresses some of these challenges. While it still does not lead to complete conversion, it improves the process significantly by preventing recombination reactions.

In the case of lignin, he succeeded in converting the macromolecules to various useful chemicals, such as vanillin (the compound that gives vanilla its distinctive aroma) and syringaldehyde (an organic compound found in wood that can serve as a building block for functional polymeric materials. Syringaldehyde is also responsible for the spicy, smoky, hot and smoldering wood aromas in whisky). These chemicals have an aromatic functionality, which means they have what chemists call a benzene ring – the simplest, organic and aromatic hydrocarbon and parent compound of numerous important aromatic compounds.

Since the 1950s, benzene was obtained solely from petroleum and is still an important building block in the manufacturing of polystyrene.

Their research takes place in the context of a wider effort in academic chemistry to promote sustainable use of resources. By converting what would have been regarded as a waste product into valuable chemicals, means that the value chain of lignin is extended, while at the same time reducing our dependence on crude oil.

Dr Sibanda says a green future for the chemical industry is possible: “We need policies that encourage the chemical and material manufacturing industries to include sustainable development in their long-terms plans. This will encourage industries to provide the same and sometimes even better quality products in a way that is environmentally sustainable. We also need more opportunities for collaborative research between industry and academia,” he concludes.

Read the original article here