A new wave of projects are using 3-D printing to develop solutions to local problems across Africa.

Also known as additive manufacturing, 3-D printing has the potential to revive Africa’s manufacturing fortunes. From healthcare to construction, here are the projects shaping Africa’s future with additive manufacturing;

Central University of Technology: MedAdd

Country: South Africa

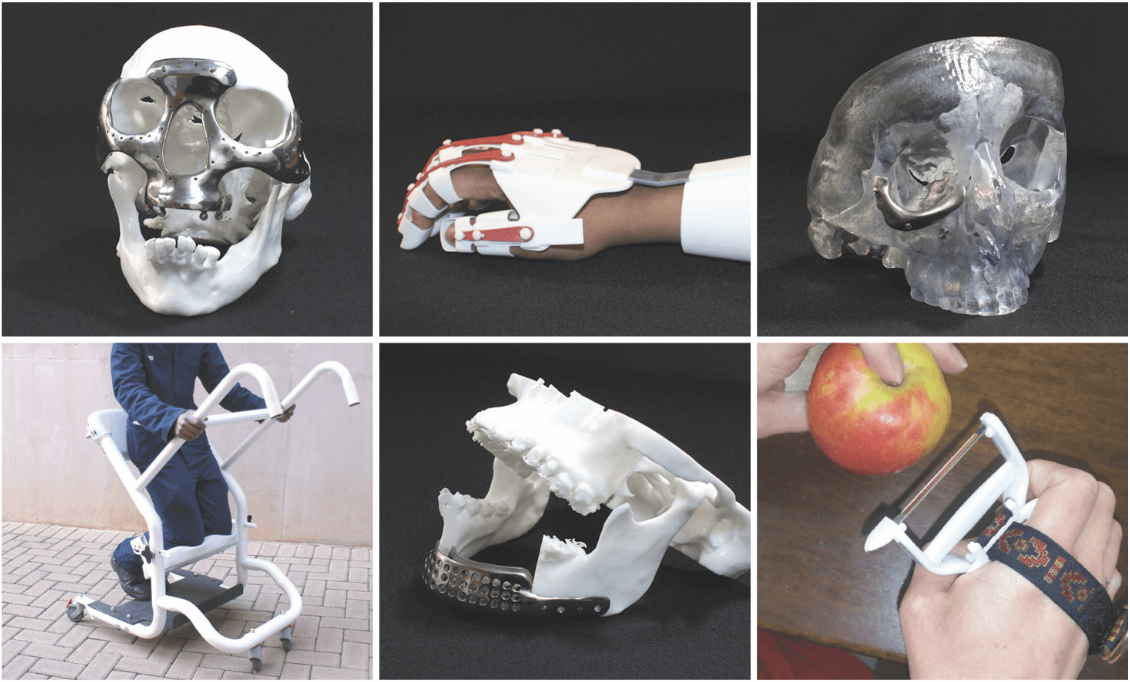

Project Overview: The MedAdd project at the Central University of Technology focuses on the application of additive manufacturing (AM) in the medical field. This initiative leverages 3D printing technologies to develop medical devices and implants tailored to individual patient needs, emphasizing innovation in healthcare solutions.

Impact: By providing customized medical solutions, the project aims to enhance patient care and recovery times. It’s a significant step towards personalized medicine in South Africa, demonstrating the potential of AM in addressing complex health challenges.

Further Information: AfricaLive Feature Article on MedAdd

University of Johannesburg: 3-D Printed Houses

Country: South Africa

Project Overview: This project by the University of Johannesburg explores the use of 3D printing technology in constructing affordable houses. It aims to tackle the housing shortage issue in South Africa by developing rapid, cost-effective building methods.

Impact: The initiative has the potential to revolutionize the construction industry by significantly reducing the time and cost of building homes, making housing more accessible to underprivileged communities.

Further Information: UJ 3D Printing Innovation To Tackle Housing Crisis

Metal Heart

Country: South Africa

Project Overview: Metal Heart is a startup backed by South Africa’s Industrial Development Corporation with an investment of R17 million. The company specializes in producing metal 3D printers for manufacturing purposes, aiming to provide South Africa with the first of its kind manufacturing hub focusing mainly on “Metal Additive Manufacturing”.

Impact: This investment is intended to create jobs in key industries and foster innovation in areas like medical devices and nanotechnology, demonstrating the government’s commitment to advancing 3D printing technologies.

Further Information: https://metalheart.co.za/

Woelab Lomé

Country: Togo

Project Overview: Originating from Togo, Woelab Lomè is an innovation hub where the first African 3D printer, entirely made from electronic waste, was created in 2013.

Woelab Lomé developed into one of the leading Fab Labs (short for Fabriaction Laboratories) in Africa and is at the forefront of fostering technological innovation in Togo.

This initiative is rooted in a vision to lay the groundwork for smart cities across Togo by nurturing smart citizens. The labs, accessible to everyone at no cost, aim to empower individuals with the skills and knowledge in various technological domains.

Impact: Woelab Lomè not only exemplifies the creative recycling of electronic waste into valuable technology but also represents a significant step towards making 3D printing accessible and affordable in underserved communities. It showcases the importance of grassroots innovation in solving local challenges, such as producing affordable medical equipment and educational tools.

Further Information: https://www.fablabs.io/labs/woelab

Stampar 3D

Country: Nigeria

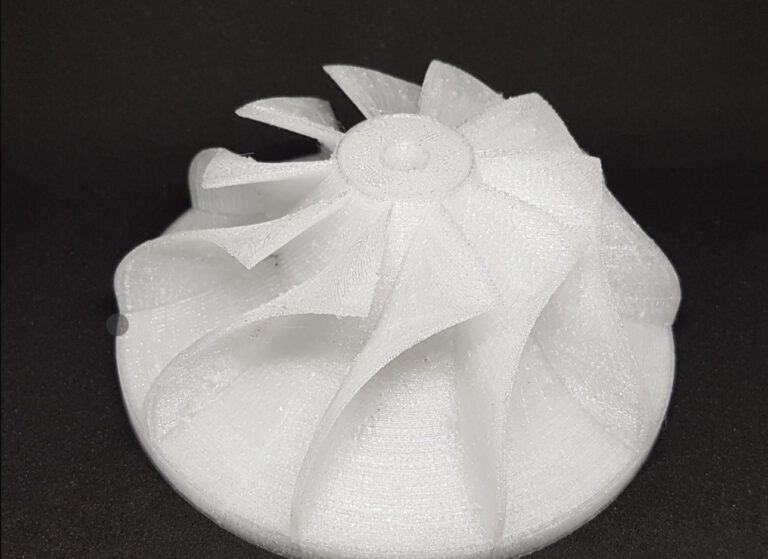

Project Overview: Stampar3D, led by engineer Akinwole Akinpelu, is a Lagos-based agency bringing 3D printing technologies to the Nigerian market. The agency focuses on manufacturing through direct 3D printing from computer-aided designs.

In addition to their commercial projects with corporations across sectors such as aerospace and food & beverage, they provide hardware labs for schools.

Stampar say 3D Printing is a great way to take hands-on classroom learning across all disciplines to the next Level.

Impact: Stampar3D exemplifies the growing interest and application of 3D printing in Nigerian manufacturing, aiming to innovate and expand market reach.

Further Information: https://stampar3d.com/

The Gambia’s 3-D Printing Farm

Country: The Gambia

Project Overview: In collaboration with Prusa Research and the support of the Czech Development Agency’s B2B Program, The Gambia is advancing a 3D printing farm initiative focused on healthcare and education.

This project aims to utilize 3D printing’s decentralized production capabilities, catering to the nation’s minimal manufacturing infrastructure. Prusa Research, known for its high-quality 3D printers and innovative contributions like antibacterial filament development, leads the effort.

Impact: The project represents a strategic approach to overcoming local manufacturing limitations, leveraging 3D printing for educational and healthcare advancements.

It embodies the potential for significant social benefits, from local production of medical aids to educational tools, setting a precedent for technology-driven development in similar markets.

Further Information: Czech Development Agency

Iroko - A Commerical 3-D Printer for Schools and Housing

Country: Pan-African (with an initial focus on Malawi, Kenya, and Zimbabwe)

Project Overview: The Iroko, launched by 14Trees, a joint venture between Holcim and British International Investment, is Africa’s first commercial construction 3D printer.

This innovation is a cornerstone in 14Trees’ efforts to revolutionize building, emphasizing affordable, low-carbon housing and educational infrastructure. The Iroko printer, co-designed with construction company PMSA, distinguishes itself by being more affordable, reliable, and mobile than its industry counterparts. It’s designed to print one- and two-story buildings for various applications, significantly lowering construction costs and carbon footprints by optimizing material use and leveraging low-carbon inks, such as Holcim’s TectorPrint. The project’s first phase rolled out at the end of 2023 and promises to significantly change African construction and manufacturing in 2024.

Impact: The Iroko 3D printer’s deployment is set to dramatically enhance the speed and sustainability of constructing homes and schools across Africa.

It promises to reduce the carbon footprint of new constructions by up to 70%, addressing critical infrastructure gaps efficiently. For instance, Malawi faces a deficit of 36,000 classrooms, a gap that could take 70 years to bridge with traditional building methods. 14Trees projects that, through 3D printing technology, this could be achieved in just a decade, revolutionizing the approach to tackling educational infrastructure shortages and creating skilled local jobs in the process