Central University of Technology’s MedAdd Project

South Africa has long relied heavily on imported medical devices, which are often expensive, unavailable, or ill-suited to local requirements.

The Medical Device Additive Manufacturing Technology Demonstrator Project (MedAdd) represents an innovative step towards transforming healthcare accessibility in South Africa. Launched by the Central University of Technology (CUT), this initiative leverages 3D printing to develop locally-made, affordable medical devices tailored to the region’s needs.

Key Points:

- MedAdd, a project by the Central University of Technology, harnesses 3D printing for medical device manufacturing.

- The project aims to reduce South Africa's reliance on imported medical devices.

- Over 1,000 patients already assisted through this initiative.

- The market for 3D printing medical devices in Africa is projected to reach USD 1,065.00 million by 2025.

Contents:

- 01. Introduction to MedAdd

- 02. By The Numbers: 3-D Printing and Medical Devices in Africa

- 03. MedAdd Serving Over 1000 Patients

- 04. Local Impact

- 05. Future Impact

- 06. Frequently Asked Questions (FAQ)

Introduction to MedAdd

South Africa’s dependence on medical device imports strains healthcare budgets and leaves many hospitals and clinics lacking vital equipment.

MedAdd’s Solution: Localized 3D Printing

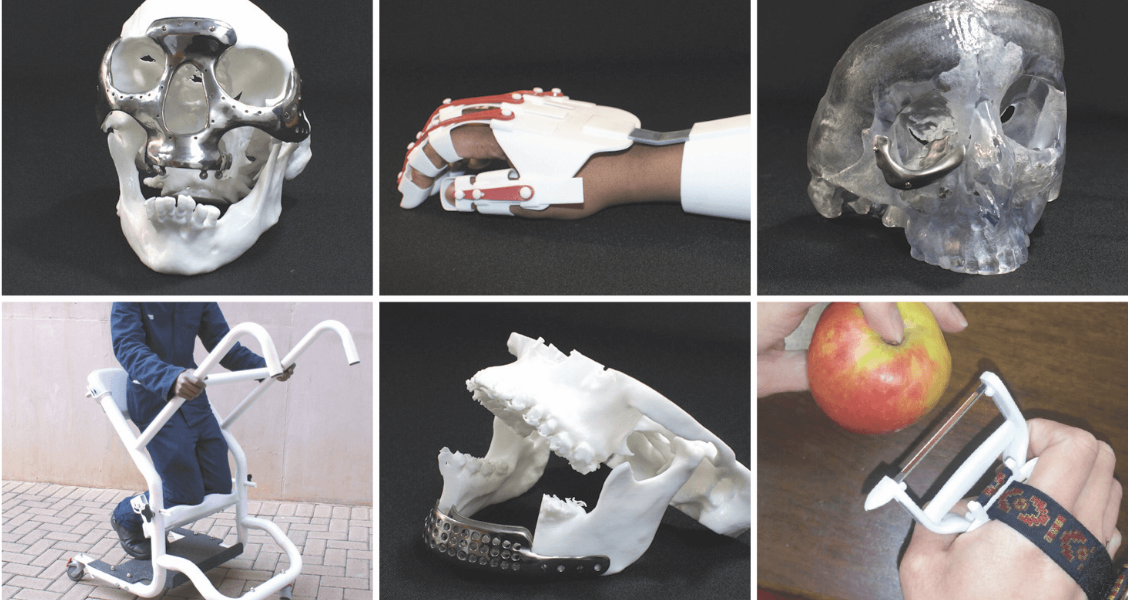

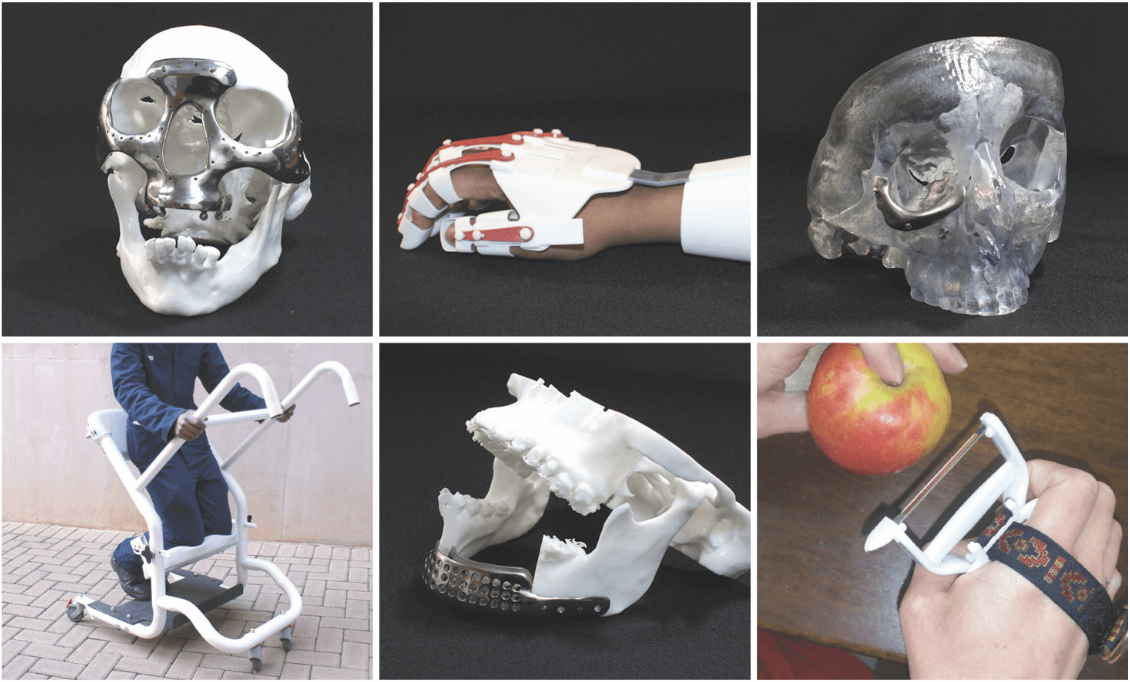

MedAdd provides a groundbreaking solution through localized 3D printing of medical devices. By manufacturing customized implants, prosthetics, and surgical tools, the project aims to reduce South Africa’s reliance on imports while enhancing access to essential, affordable healthcare solutions.

By using additive manufacturing (3D printing), MedAdd seeks to bridge the innovation gap in the production of medical devices, particularly for small businesses and hospitals that struggle with the high costs of imported medical equipment.

The project is a collaboration between the Department of Science and Innovation (DSI) and CUT, specifically through the university’s Centre for Rapid Prototyping and Manufacturing (CRPM).

By the Numbers: The Potential of 3-D Printing in the Medical Device Industry in Africa

- The broader Africa 3D printing medical devices market is projected to reach USD 1,065.00 million by 2025, with a CAGR of 17.04% (Insights10, 2022).

- 3D printing can reduce dependence on imported medical devices, often unavailable or prohibitively expensive, by enabling local production.

- Patients benefit from improved access to affordable, personalized medical devices: prosthetics, implants, surgical guides, etc.

- Developing markets will benefit from reduced reliance on foreign specialists for complex procedures with locally fabricated devices.

Over 1000 Patients Using MedAdd Devices

MedAdd utilizes additive manufacturing technology to produce customized medical implants and devices. The goals are to foster local manufacturing capabilities, reduce dependence on imported medical devices, and ultimately improve health outcomes in South Africa. The project also aims to stimulate economic growth and manufacturing within the province.

The project has the potential to drastically improve healthcare accessibility in South Africa by making medical devices more affordable and tailored to individual needs. It can help hospitals and clinics, especially in remote areas, to have better access to vital medical equipment.

As of now, over 1,000 patients have been assisted through the CRPM’s efforts, supported by state and private hospitals and funding from the DSI, TIA, and other partners. Local use-cases and designs for the medical industry have been developed, including portable 3D-printed mechanical ventilators by the University of Johannesburg.

Local Impact: Life Changing Interventions

The BBC covered the MedAdd success story, highlighting how 3-D printed medical devices changed the life of a local gunshot victim Princess Moshona.

Future Impact: CUT leading the way in a transformative sector

The MedAdd project represents an important development in utilizing 3D printing technology for localized medical device manufacturing in Africa.

The project’s success could pave the way for broader adoption of 3D printing for healthcare applications across Africa.

Collaborative efforts between stakeholders across sectors will be key in smoothly transitioning towards technological advancement in healthcare. Initiatives promoting access to 3D printing technology, like South Africa’s Fab Lab network, can contribute significantly.

South Africa’s leadership in this domain, with a projected market size of USD 70 million by 2030, sets a benchmark for other African nations. The emergence of technology hubs and fab labs, like the Togolese fab lab Woelab Lomé, reflects a growing ethos of innovation across the continent, which is instrumental in adopting new technologies for societal needs.

MedAdd highlights the possibilities of localized innovation in addressing region-specific healthcare challenges. As 3D printing becomes more accessible, similar initiatives could gradually transform medical device markets across Africa by enabling needs-based, affordable products.

This democratization of technology will enable a broader range of players – from small businesses to research institutions – to participate in the medical device market, fostering a culture of innovation that is deeply rooted in local needs and conditions.

Frequently Asked Questions (FAQ)

MedAdd is an initiative by the Central University of Technology in South Africa, leveraging 3D printing technology to develop affordable, locally-made medical devices tailored to the region's specific healthcare needs.

It was launched to reduce the country's dependence on expensive and sometimes ill-suited imported medical devices, and to improve healthcare accessibility by creating devices that are better suited to local requirements.

Over 1,000 patients have benefited from the medical devices and solutions provided by the MedAdd project.

The market for 3D printing medical devices in Africa is expected to reach approximately USD 1,065.00 million by 2025.

MedAdd specializes in manufacturing customized implants, prosthetics, and surgical tools using additive manufacturing (3D printing) technology.

It improves access to affordable, personalized medical devices like prosthetics and implants, enhances surgical accuracy and outcomes, and reduces reliance on foreign specialists.

Sources:

- The Insight Partners: https://www.theinsightpartners.com/categories/medical-device/

- Insights10: https://www.insights10.com/reports/medical-devices/

- Fact.MR: https://www.factmr.com/report/248/3d-printing-medical-devices-market

- MarketsandMarkets: https://www.marketsandmarkets.com/PressReleases/3d-printing.asp

- ScienceDirect: https://www.sciencedirect.com/science/article/pii/B9780128134771000128