The Centre for Rapid Prototyping and Manufacturing (CRPM) at the Central University of Technology, Free State, is at the forefront of medical 3D printing innovation in Africa. With support from South Africa’s Department of Science and Innovation, CRPM is developing groundbreaking solutions that are revolutionising healthcare across the continent.

From customised implants to veterinary applications, these innovations are improving patient outcomes and making advanced medical treatments more accessible. What are the most innovative 3D printed solutions coming out of CRPM today? And how do these projects seek to shape the future of healthcare in Africa? AfricaLive presents 6 projects to watch:

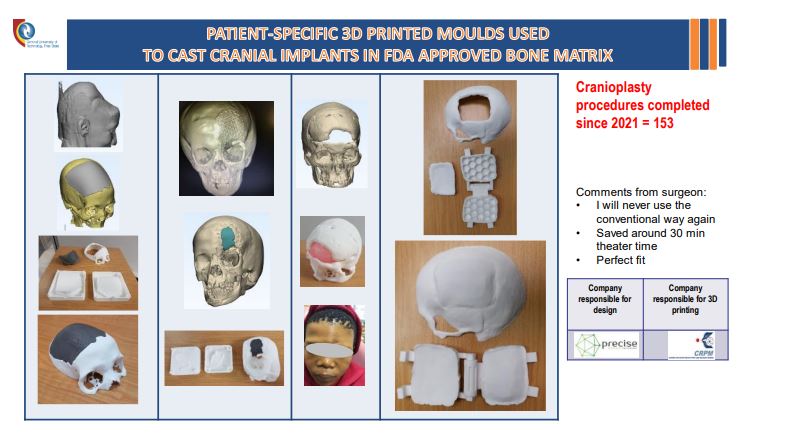

1. Patient-Specific 3D Printed Moulds for Cranial Implants

Project Overview: CRPM is creating patient-specific moulds for cranial implants using 3D printing technology. This process involves converting 2D CT scan data into 3D models, which are then used to print precise moulds for casting implants.

How it works: The patient’s CT scan data is processed to create a digital 3D model. This model is used to design and 3D print a mould, which is then used to cast a custom-fit cranial implant.

Impact: This technology allows for the production of perfectly fitted implants, reducing surgery time and improving patient outcomes. It also makes complex cranial surgeries more accessible in regions with limited access to specialised medical equipment.

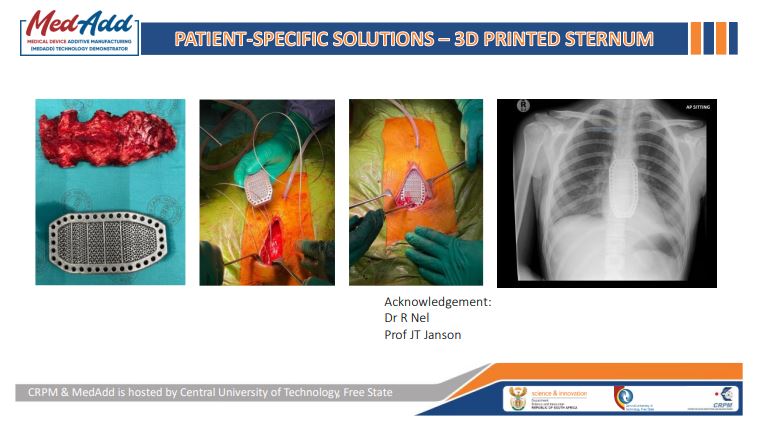

2. 3D Printed Sternum Implants

Project Overview: CRPM is developing 3D printed titanium sternum implants for patients requiring chest wall reconstruction.

How it works: Using patient-specific CT data, a custom sternum implant is designed and directly 3D printed in titanium using laser melting technology.

Impact: These custom implants provide better fit and function compared to standard implants, potentially reducing complications and improving patient recovery. The ability to produce these implants locally also reduces costs and waiting times for patients.

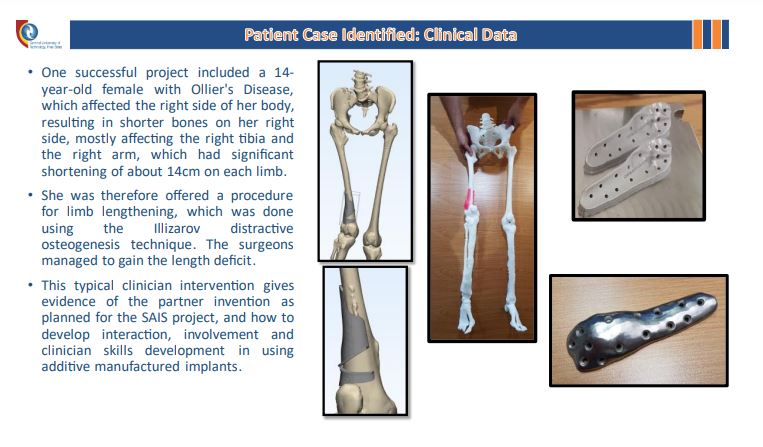

3. Spinal Cages

Project Overview: CRPM is creating customised spinal cages using 3D printing technology to treat various spinal conditions.

How it works: Patient-specific spinal cages are designed based on CT scans and 3D printed in biocompatible materials like titanium.

Impact: These custom spinal cages can provide better stability and fusion rates compared to off-the-shelf implants, potentially improving outcomes for patients with complex spinal conditions. The ability to rapidly prototype and produce specialised surgical guides and instruments also improves surgical precision and reduces operation times.

4. Veterinary Applications

Project Overview: CRPM is extending its 3D printing expertise to veterinary medicine, creating custom implants and prosthetics for animals.

How it works: Similar to human applications, CT scans of animals are used to design and 3D print custom implants or prosthetics.

Impact: This technology is improving the quality of life for animals that might otherwise be euthanized due to severe injuries or deformities. The most notable example is Max the macaw, who received a 3D printed titanium beak prosthesis.

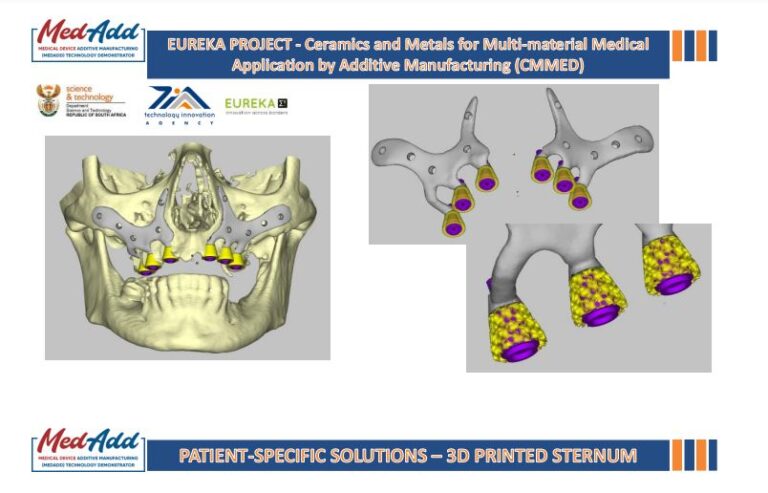

5. Biocompatible Multi-Material Implants

Project Overview: Through the CMMMed project, CRPM is developing new biocompatible, medical-grade metallic and ceramic composite materials for 3D printing of advanced medical devices.

How it works: The project focuses on creating materials with multiple desired biological responses such as antimicrobial, osseointegrative, and anti-thrombotic properties.

Impact: These advanced materials could lead to implants with improved functionality and biocompatibility, potentially reducing rejection rates and improving long-term patient outcomes. This research also reduces dependence on imported medical materials and devices.

6. Resorbable Bone-Regenerating Scaffolds

Project Overview: CRPM is working on developing small- to medium-load-bearing resorbable, bone-regenerating scaffolds using additive manufacturing.

How it works: Using specialised biocompatible and resorbable materials, CRPM 3D prints scaffolds that can support bone growth and gradually dissolve as new bone forms.

Impact: These scaffolds could revolutionise bone repair procedures, promoting faster and more complete healing while reducing the need for follow-up surgeries to remove implants. This technology has the potential to significantly improve patient recovery and reduce healthcare costs.

Further Information: CRPM Bone Regeneration Research

As CRPM continues to innovate and expand its capabilities, it is poised to play a crucial role in advancing healthcare across the continent, making advanced medical treatments more accessible and improving patient outcomes.

The Centre’s ISO 13485 certification for 3D printing of medical devices, the first of its kind in Africa, further underscores its commitment to producing high-quality, safe medical innovations. Through these initiatives, CRPM is not only addressing immediate healthcare needs but also building local capacity for medical device innovation and manufacturing in Africa.