University of Botswana Pioneers 3D-Printed Medical Innovations, Collaborating with South Africa’s Central University of Technology

Key Points:

- University of Botswana (UB) is using 3D printing technology to revolutionize disease treatment and improve healthcare for Batswana.

- A 17-year-old patient with Ollier's Disease benefited from a custom hip implant designed at UB's Faculty of Medicine Regenerative Medicine Laboratory.

- The project involves collaboration between UB and the Central University of Technology (CUT) in South Africa for implant development.

- UB is also developing 3D-printed alternatives for COVID-19 related medical supplies.

- The research is funded by Lloyds Register Foundation, a UK-based charity, with a grant of P376,781 (£25,000).

- This initiative aligns with broader African efforts in 3D-printed medical devices, such as CUT's MedAdd project in South Africa.

Revolutionizing Healthcare Through 3D Printing Technology

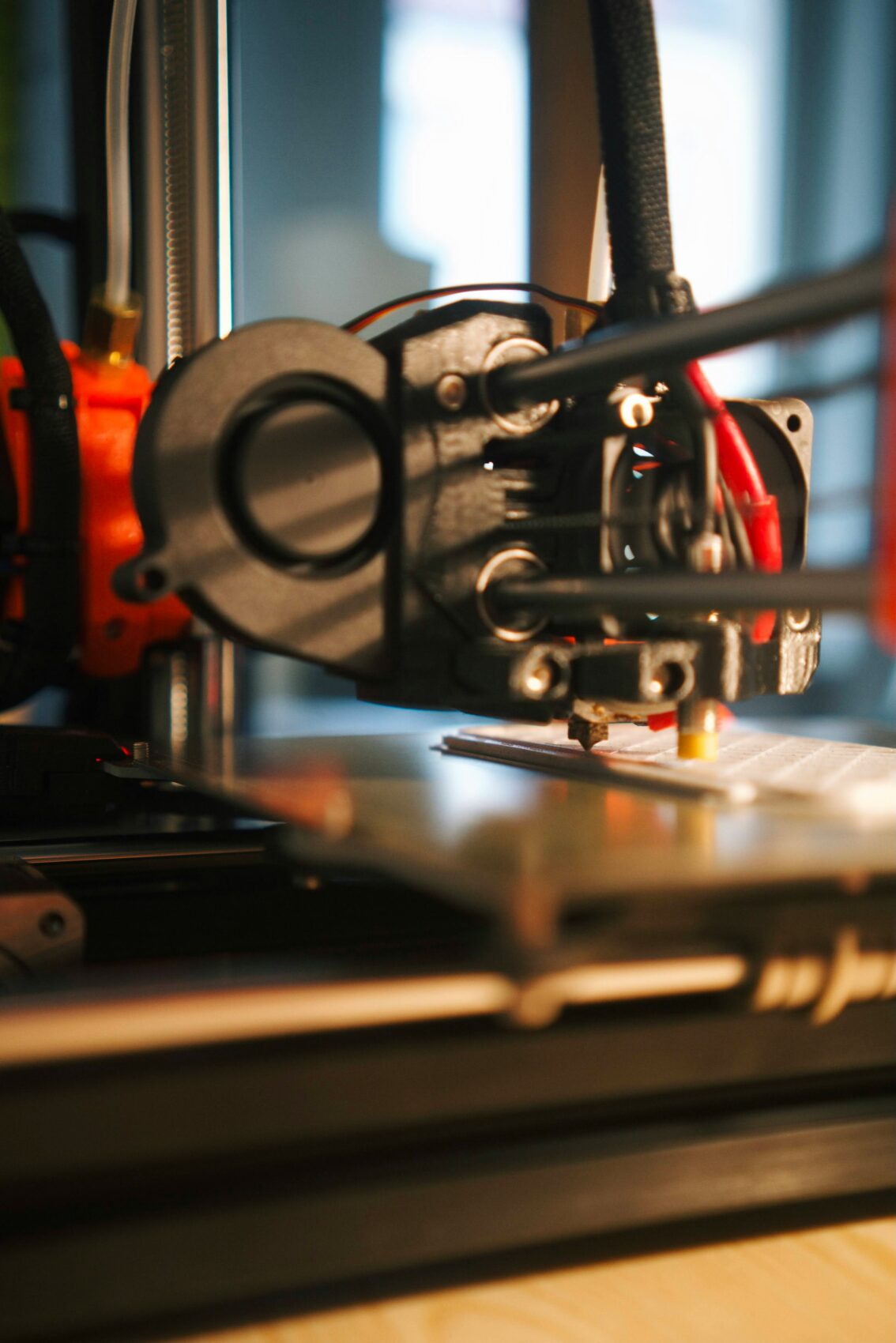

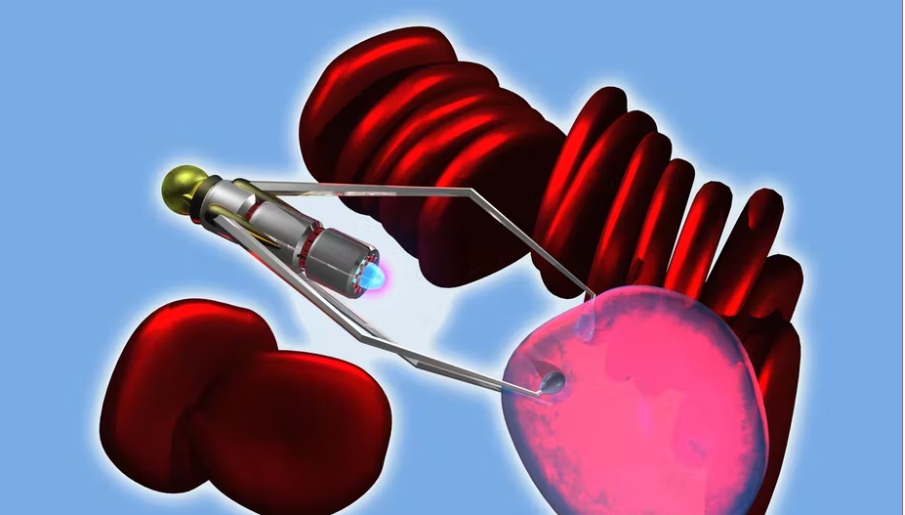

The University of Botswana (UB) has embarked on an ambitious journey to revolutionize disease treatment through 3D printing technology, aiming to improve the health of Batswana. This initiative aligns with UB’s strategic goal of creating societal impact through cutting-edge research and innovation. By leveraging 3D printing technology, which has shown significant potential in improving medical treatments in developed countries, UB is positioning itself at the forefront of medical innovation in Africa.

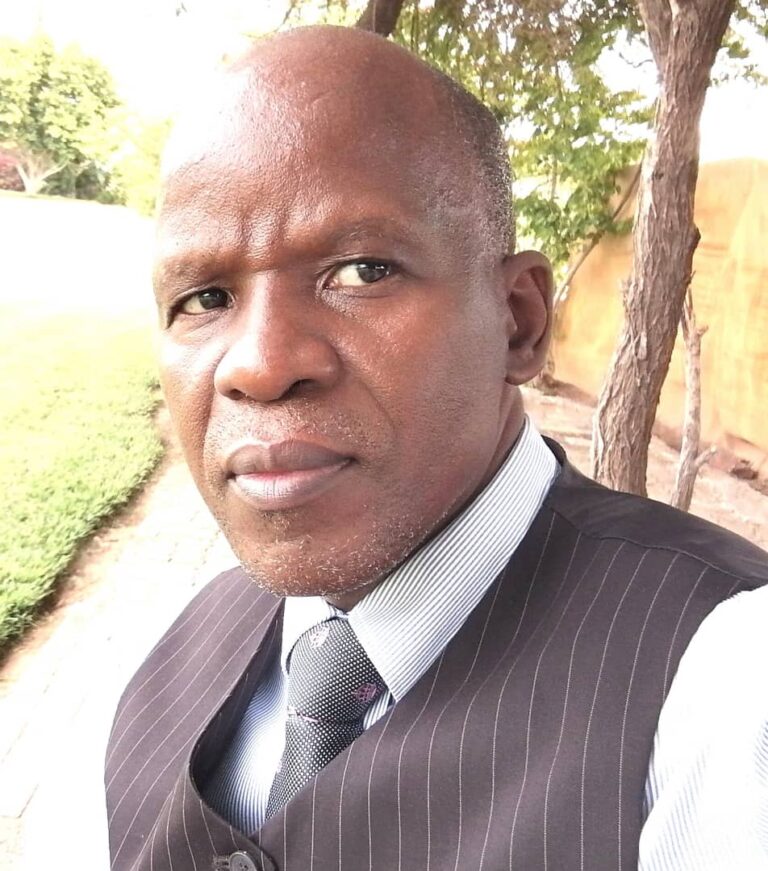

Dr. Shathani Nkhwa, the principal investigator and a biomedical and biomaterial tissue engineer at UB’s Faculty of Medicine, leads this groundbreaking project. The initiative has already demonstrated its potential through the successful treatment of a 17-year-old patient with Ollier’s Disease, a rare skeletal disorder characterized by noncancerous benign growths of cartilage within the bones.

Customized Solutions for Complex Medical Conditions

The case of the 17-year-old patient highlights the transformative potential of this technology. Prior to surgery, the patient struggled with impaired walking, falls, low back pain, and self-image issues due to a deformed right lower limb. The UB team offered a solution involving corrective osteotomy and fixation with a custom-made implant, along with surgical correction of the ankle.

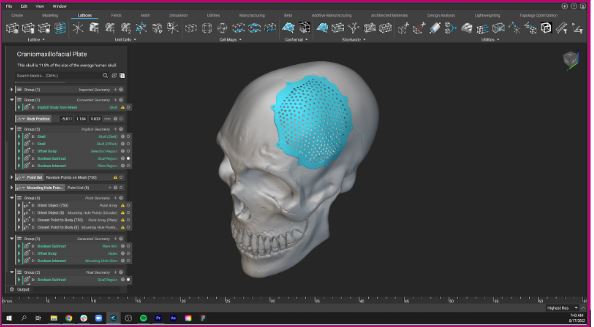

Dr. Nkhwa explains the advantage of their approach: “It would allow detailed pre-operative planning and design when using 3D printed models and in turn assist in the manufacturing of the right implant.” This precision is particularly crucial in cases with unique anatomical challenges, where conventional implants might not be suitable.

Collaborative Efforts Driving African Medical Innovation

The process involves a collaborative effort between various institutions, showcasing the potential of pan-African partnerships in advancing medical technology. Initially, the patient’s CT scan is used to construct a 3D anatomical model at the Botswana Institute of Technology Research and Innovation (BITRI). This model is then used by surgeons to plan the procedure and design the required implant.

In a key step highlighting international collaboration, the final implant design requirements are sent to the Central University of Technology (CUT) in South Africa for implant development. This collaboration between UB and CUT exemplifies the potential of cross-border partnerships in advancing medical technology in Africa.

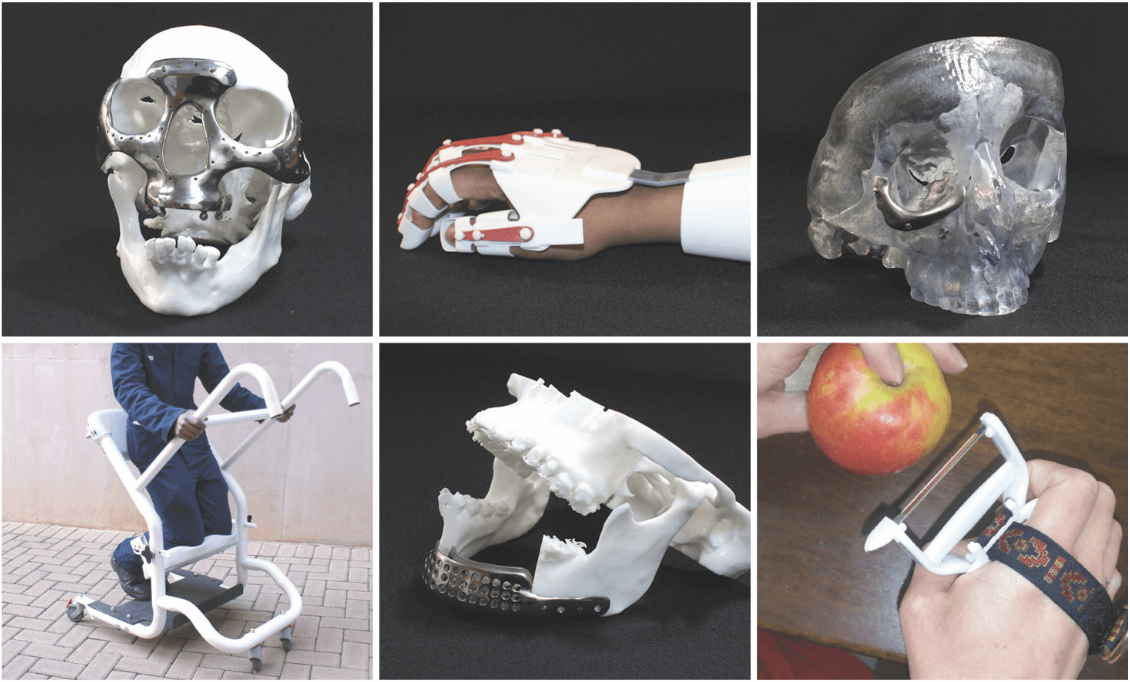

Interestingly, this collaboration aligns with CUT’s own initiatives in 3D-printed medical devices. CUT’s Medical Device Additive Manufacturing Technology Demonstrator Project (MedAdd) aims to reduce South Africa’s reliance on imported medical devices by leveraging 3D printing technology. The MedAdd project has already assisted over 1,000 patients, demonstrating the significant impact of such initiatives in the region

Applications for 3-D Printed Medical Devices

The University of Botswana’s pioneering work in 3D-printed medical devices is opening up a wide range of possibilities in healthcare. Beyond this specific case, Dr. Nkhwa and her team are exploring various applications that could transform medical practices across multiple specialties.

One key area identified by Dr. Nkhwa is pre-surgical planning. Patient-specific 3D models derived from CT or MRI scans have become invaluable tools for healthcare professionals, allowing for detailed pre-operative planning and intra-operative visualization. This approach is particularly beneficial in complex procedures such as tumor excisions.

Dr. Nkhwa explains that 3D printed anatomical models help doctors save time in preparing for surgery by allowing for intra-operative visualization and device sizing or pre-fitting of medical devices for both routine and highly complex procedures. This approach not only improves surgical precision but also serves an educational purpose. Doctors can use these models to explain procedures to patients or medical students, enhancing understanding and potentially reducing patient anxiety.

The ability to create customized medical devices is perhaps the most transformative aspect of this technology. Dr. Nkhwa emphasizes that instead of using one-size-fits-all generic implants, they can offer surgeons options to make unique treatments available to patients with complex cases.

This customization extends beyond implants to include prostheses, orthoses, and even dental devices. Personalized devices offer numerous advantages, including improved fit and comfort for patients, better surgical outcomes due to tailored solutions, potential for faster recovery times, and reduced risk of complications from ill-fitting devices.

The applications of 3D printing in medicine are vast and growing. In orthopedic surgery, custom implants and patient-matched bone plates can be created for complex cases. Plastic and reconstructive surgery benefit from patient-specific implants for treating deformities or trauma.

The technology allows for the creation of customized, comfortable prostheses with unique features that would be impossible with traditional manufacturing methods. In orthodontics and dentistry, highly customized devices can be produced at scale. Even veterinary medicine is seeing advancements with custom implants and prostheses for animal patients.

The COVID-19 pandemic highlighted the potential of 3D printing in addressing sudden healthcare challenges. The UB Faculty of Medicine quickly pivoted to develop 3D-printed alternatives for critical supplies.

These include nasal swabs for COVID-19 testing, respirator oxygen tube adaptors/connectors, and venturi devices for oxygen therapy. Dr. Nkhwa notes that they are further refining these designs, particularly the nasal swabs, to better suit the African demographic. These innovations demonstrate the flexibility and rapid response capabilities of 3D printing technology in healthcare.

While the potential of 3D printing in healthcare is immense, there are challenges to overcome. Currently, there’s a limited range of biocompatible materials suitable for medical 3D printing, though ongoing research is expanding these options.

Personalized medical devices also present unique regulatory challenges, and the team at UB is working on establishing traceable design processes to streamline future approvals. Additionally, while production costs can be lower, the initial design process for personalized devices can be resource-intensive.

Economic Impact and Market Potential

The potential economic impact of these innovations is substantial. According to recent projections, the broader African 3D printing medical devices market is expected to reach USD 1,065.00 million by 2025, with a compound annual growth rate of 17.04%. This growth underscores the significant market potential for initiatives like UB’s and CUT’s MedAdd project.

By enabling local production of medical devices, these projects can reduce dependence on expensive imports, making healthcare more accessible and affordable. Furthermore, they have the potential to stimulate economic growth and manufacturing within their respective regions.

A New Era of African Medical Innovation

As the University of Botswana continues to push the boundaries of medical innovation, its collaboration with institutions like CUT in South Africa paves the way for a new era of personalized, efficient healthcare solutions in Africa. These initiatives not only address immediate medical needs but also position African institutions as contributors to cutting-edge medical technology on the global stage.

The success of projects like UB’s 3D printing initiative and CUT’s MedAdd demonstrates the potential for localized innovation in addressing region-specific healthcare challenges. As 3D printing technology becomes more accessible, similar initiatives could transform medical device markets across Africa, enabling needs-based, affordable products and fostering a culture of innovation that is deeply rooted in local needs and conditions.

Share

Search by Category

Related Stories

Subscribe to the Future of Africa newsletter here.

You will hear once per month directly from African CEOs and international investors shaping the future of sustainable African development.